7

INTRODUCTION

2.1.2.4

The tests for Grade 1 in Table 1 shall be repeated using a test wire

comprising a strip of wetted cotton cloth which has been attached to the

fixture by tourniquet action.

2.1.3 Load Release Hardware

2.1.3.1

The device shall be subjected to safety testing as shown in Table 2. The

anti-ligature device shall be mounted in a representative manner to

include any fixed associated mounting device on a surface which is also

of representative orientation to the vertical and horizontal. The ligature

test wire shall be either plastic coated with a fabric or metal core, or

nylon with a breaking strength >300N at the correct diameter for Test 2

and >20N at the correct diameter for Test 3.

2.1.3.2

For devices designed to be mounted on vertical surfaces, the test wire

shall be tied around the device as close to the mounting fixture as is

possible using a simple slip knot (see Annex B), and Test 2 carried out

using the required ligature test load which shall be applied by a weight,

in one direction, being downward. The device will release at a load

of less than 196N. Test 3 shall be carried out for any fixed associated

mounting device. If it is not possible to either start or complete the test

because the test wire does not remain attached to the anti-ligature

device or its associated amounting device, the test will be deemed

successful.

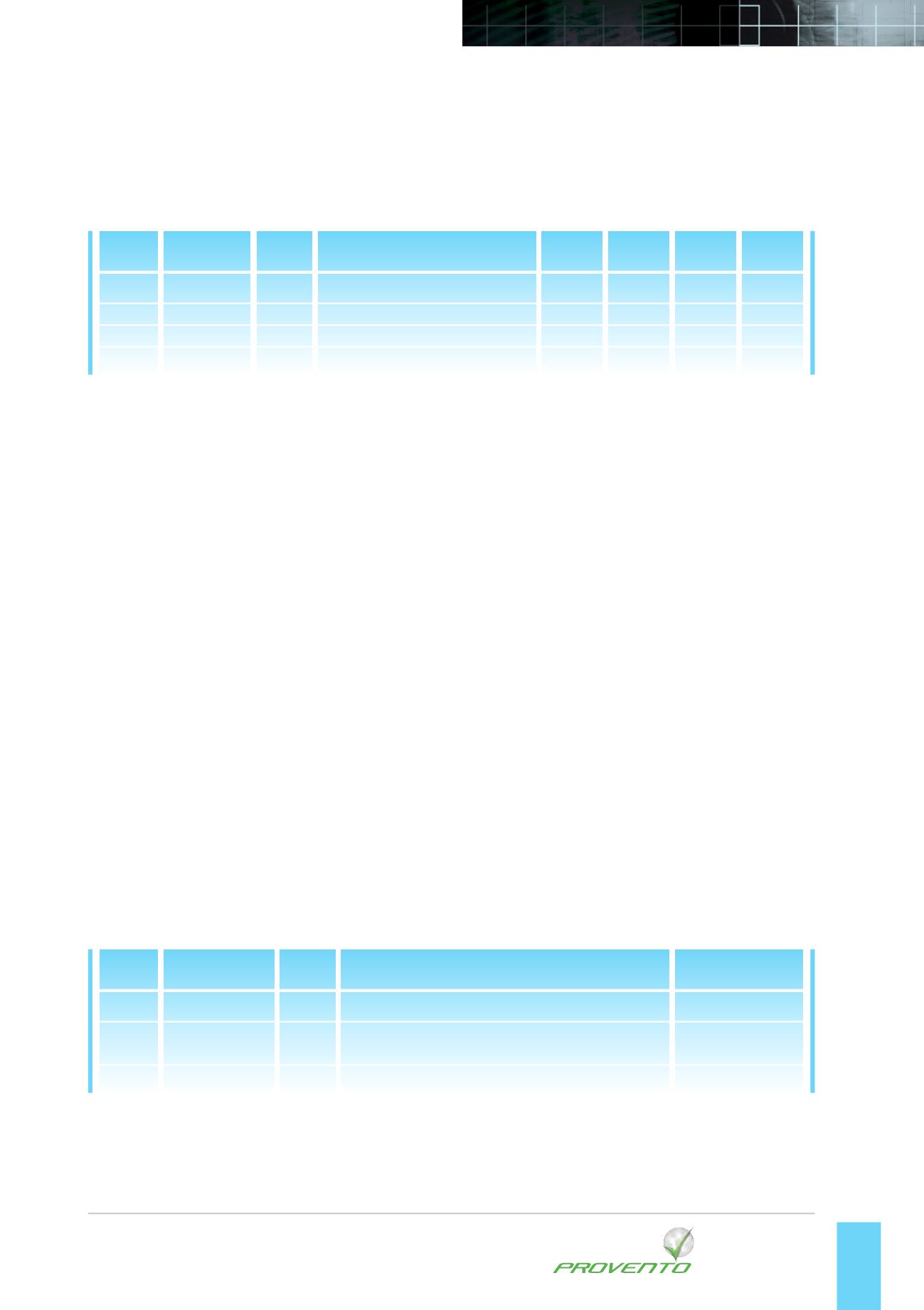

Table 1

Test

Sub Clause Figure Code

Safety Grade Criteria

Grade 1 Grade 2 Grade 3 Grade 4

5.5

B1

Ligature test wire diameter

>4mm 2mm 1mm 0.5mm

1

2.1.2.2 or

Ligature test load

5N

5N

5N

5N

2.1.2.3

+0 /-0.5N +0 /-0.5N +0 /-0.5N +0 /0.5N

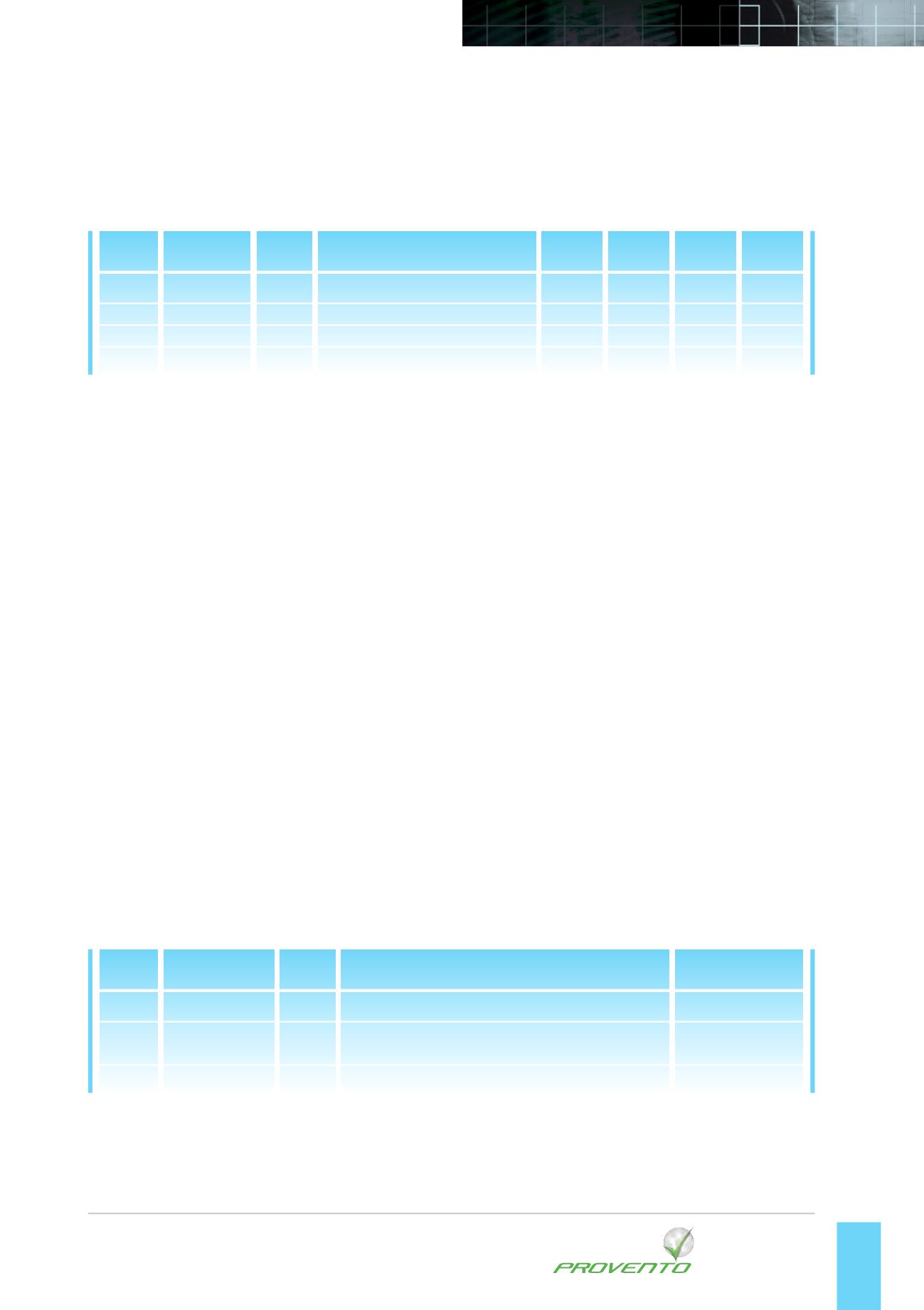

Table 2

2.1.3.3

For devices designed to be mounted on horizontal and all other non-ver-

tical surfaces, the test wire shall be tied around the device as close to the

mounting fixture as is possible using simple slip knot and Test 2 carried

out using the required ligature test load which shall be applied by a

weight downwards in a plane parallel to the mounting surface. Test 3

shall be carried out for any associated mounting device. If it is not

possible to either start or complete the test because the test wire does

not remain attached to the anti-ligature device or its associated

mounting device, the test will be deemed successful.

2.1.3.4

If there are two or more fixings, one or more of the devices will release

when a load of less than 196N is applied at a point equi-distant between

two fixings.

2.1.3.5

The tests for Grade 1 in Table 2 shall be repeated using a test wire

comprising a strip of wetted cotton cloth which has been attached to the

fixture by tourniquet action.

Test

Sub Clause Figure Code

Test Parameter

5.5

B1

Ligature test wire diameter

>4mm

2

2.1.3.2 or 2.1.3.3

Device test load per fixture

<196N

or 2.1.3.4

3

2.1.2.2 or 2.1.2.3

Associated mounting device test load

See Table 1

01366 386 800

Dorplan